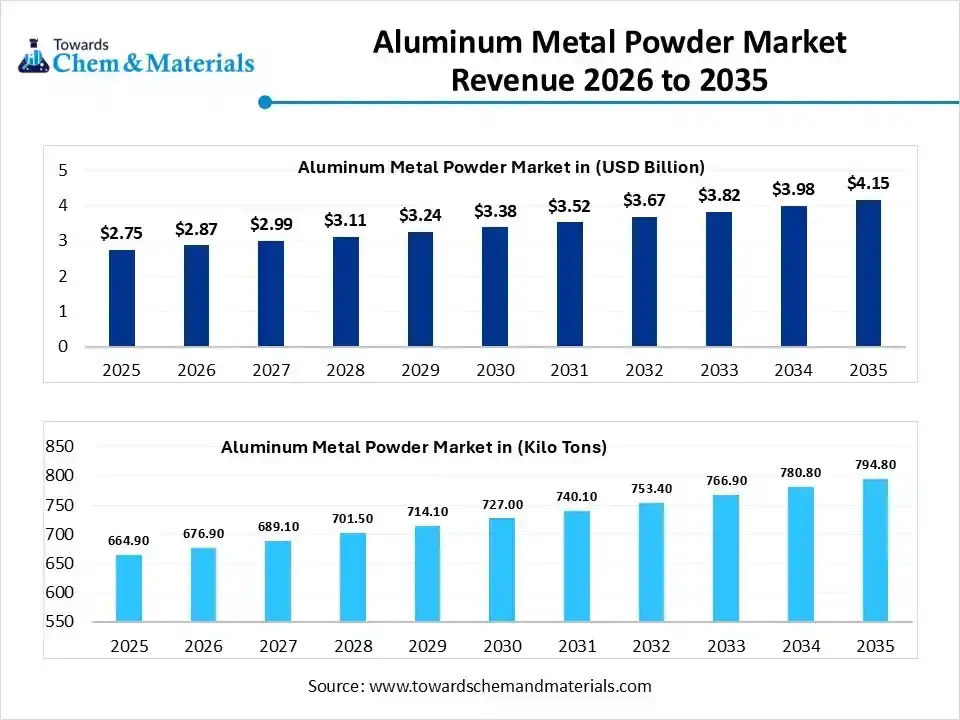

Aluminum Metal Powder Market Volume Worth 794.8 Kilo Tons by 2035

According to Towards Chemical and Materials, the global aluminum metal powder market volume was valued at 664.9 kilo tons in 2025 and is expected to be worth around 794.8 kilo tons by 2035, exhibiting at a compound annual growth rate (CAGR) of 46.23% over the forecast period from 2026 to 2035.

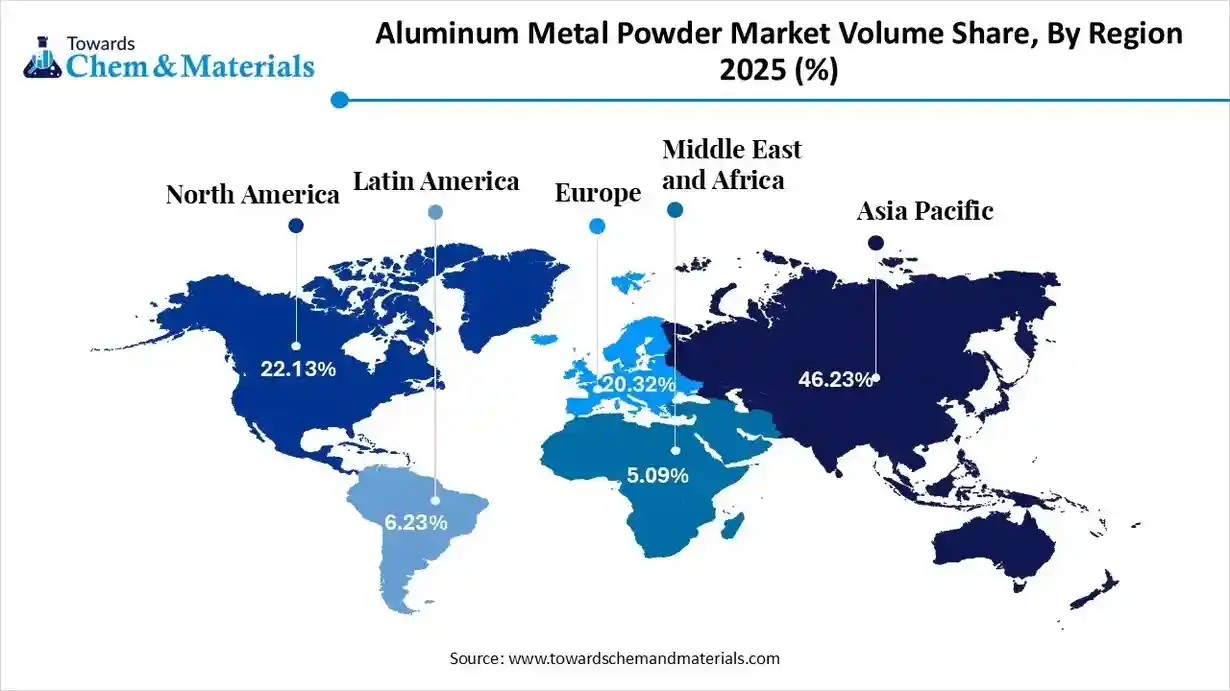

Ottawa, Jan. 22, 2026 (GLOBE NEWSWIRE) -- The global aluminum metal powder market size was estimated at USD 2.75 billion in 2025 and is expected to increase from USD 2.87 billion in 2026 to USD 4.15 billion by 2035, growing at a CAGR of 4.19% from 2026 to 2035. In terms of volume, the market is projected to grow from 664.9 kilo tons in 2025 to 794.8 kilo tons by 2035. growing at a CAGR of 46.23% from 2026 to 2035. Asia Pacific dominated the aluminum metal powder market with the largest volume share of 46.23% in 2025. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/6135

Shaping Tomorrow: Empowering Industries with Aluminium Metal Powder

Aluminum metal powder is a material composed of finely divided particles of elemental aluminum valued for its chemical reactivity and high heat of combustion, by using processes such as gas atomization used mostly used for pigments and coatings. By serving as a critical feedstock for 3D printing, lightweight aerated concrete, and powder metallurgy and also acts as a chemical foaming agent to create structural porosity.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Aluminium Metal Powder Market Report Highlights

- The Asia Pacific dominated the global aluminum metal powder market with the largest volume share of 46.23% in 2025.

- The aluminum metal powder market in North America is expected to grow at a substantial CAGR of 2.93% from 2026 to 2035.

- The Europe aluminum metal powder market segment accounted for the major volume share of 20.32% in 2025.

- By product type, the atomized aluminum powder segment dominated the market and accounted for the largest volume share of 58.60% in 2025.

- By product type, the specialty aluminum powder segment is expected to grow at the fastest CAGR of 3.82% from 2026 to 2035 in terms of volume.

- By process, the atomization segment led the market with the largest revenue volume share of 58.6% in 2025.

- By purity level, the high purity segment dominated the market and accounted for the largest volume share of 39.8% in 2025.

- By end-use sector, the automotive and transportation segment led the market with the largest revenue volume share of 36.5% in 2025.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6135

Private Industry Investments for Aluminium Metal Powder:

- Runaya (in partnership with Eckart): Runaya, a Vedanta Group company, is investing in India's first green, spherical gas-atomized aluminum powder plant to produce material for high-tech applications like aerospace, space exploration, and solar technology.

- Kymera International: In February 2024, Kymera International expanded its presence in the specialty metal powder market by acquiring the majority of Royal Metal Powders Inc.'s assets, including their atomized metal powder capabilities.

- Gränges Powder Metallurgy: This new business unit, established in September 2024, aims to become a leading manufacturer of custom and specialty aluminum powders for the growing additive manufacturing market, targeting high-growth sectors such as automotive and aerospace.

- Valimet, Inc. and APWORKS GmbH: In April 2025, these two companies signed a non-binding agreement to atomize Scalmalloy alloy powder domestically in the United States, specifically for use in additive manufacturing.

What Are the Major Trends in the Aluminium Metal Powder Market?

- Focus on Sustainability: The increasing focus on environmental regulations and consumer demand is driving the adoption of green manufacturing, utilizing more recycled aluminium and developing energy-efficient production methods ensure sustainable products with safety.

- Advanced Powder Metallurgy for Complex Parts: Innovation in powder metallurgy allows for the production of components with superior mechanical properties and higher density that offer cost-effective and high-strength alternatives.

-

Expansion in Industrial Application: The rising demand in aerospace, defense, construction, and electronics due to the material’s high energy output and lightweight properties.

Aluminum Metal Powder Market Report Scope

| Report Attribute | Details |

| Market Size and Volume in 2026 | USD 2.87 Billion / 676.9 Kilo Tons |

| Revenue Forecast in 2035 | USD 4.15 Billion / 794.8 KiloTons |

| Growth rate | CAGR 4.19% |

| Forecast Period | 2026 - 2035 |

| Base Year | 2025 |

| Units Considered | Value (Billion / Million), Volume (Kilo Tons) |

| Dominant Region | Asia Pacific |

| Segment Covered | By Product Type & Morphology, By Production Process (Technology), By Purity Level, By End-Use Sector, By Region |

| Key companies profiled | Valimet, Inc., Höganäs AB, AMG Advanced Metallurgical Group, Toyo Aluminium K.K., U.S. Metal Powders, Inc. (AMPAL) (USA), Rusal (Russia), Kymera International , ECKART GmbH (Germany), MMP Industries Ltd. (India), The Metal Powder Company Limited (MEPCO) (India), Zhangqiu Metallic Pigment Co., Ltd. (China), Xinfa Group Co., Ltd. (China), Arasan Aluminium Industries (P) Ltd. (India), CNPC Powder Group Co., Ltd. (China), Angang Group (China) |

Aluminium Metal Powder Market Dynamics

Driver

The advancement in additive manufacturing (3D Printing) is a key driver of market growth. Aluminium powder with enhanced flowability and strength is the key feedstock for metal 3D printing technologies like laser powder bed fusion (LPBF).3D printing enables complex geometries and lightweight structural parts, which are pushing manufacturers and AM technology providers towards strategic partnership which foster innovation.

Restraint

The aluminum metal powder market shows significant restraints, primarily due to its high energy consumption and its inherent flammability and health hazards of fine aluminum dust, necessitating investment in rigorous safety compliance. Additionally, the high-cost and complex manufacturing process restraints market growth.

Market Opportunity

Can Emerging Applications Reshape the Aluminium Metal Powder Market?

The emerging opportunity in renewable energy infrastructure and advanced electronics. The high-purity aluminum powder utilized in solar photovoltaic cells, essential component in hydrogen storage technologies. Additionally, it also create opportunity in energy-efficient construction materials which provide superior insulation for green buildings.

Accelerating Future: Technologies with Advanced Aluminium Metal Powders

The market is revolutionized by AI-driven materials informatics and smart atomization control. Machine learning discovers high-strength,3D-printable powders while computer vision systems maintain particle morphology. The integration of digital twins and predictive analytics optimized energy consumption and reduced equipment downtime, enabling precision for next-generation aerospace and electric vehicle components.

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Aluminium Metal Powder Market Segmentation Insights

Product Type & Morphology Insights

How did the Atomized Aluminium Powder Segment dominate the Aluminium Metal Powder Market in 2025?

The dominance of the atomized aluminum powder segment is attributed to its superior shape and high purity, crucial for advanced industrial standards. It offers excellent flowability and packing density, vital for additive manufacturing and high-precision 3D printing, ensuring uniform layers and consistent melting in laser processing, especially in aerospace and medical sectors. Its enhanced chemical reactivity and thermal conductivity make it prominent for high-energy uses, like EV thermal management.

The specialty aluminium powders segment is anticipated to grow fastest during the projected period because it provides highly engineered solutions for high-performance requirements, driven by demand for high-strength, lightweight alloys enhanced with elements like scandium or titanium for aerospace and sophisticated satellite use, and for electric mobility applications needing materials with superior thermal and electrical properties for battery cooling systems and conductive pastes, enabling complex 3D-printed parts and shifting from commodity materials to high-tech solutions.

Production Process Insights

Which Production Process Segment Dominates the Aluminium Metal Powder Market in 2025?

The atomization segment maintains its market dominance because it efficiently produces highly spherical, uniform particles essential for high-tech industries. Using high-pressure gas or water that ensures morphological consistency and high purity. This superior particle shape is critical for additive manufacturing and powder metallurgy, with fine control over particle size distribution, making it dynamic for aerospace, automotive, and electronics.

The electrolysis & chemical reduction segment offers significant growth during the forecast period, providing ultra-high purity powders necessary for electronics, semiconductors and EV batteries, reducing metallic impurities and contaminants, and facilitating applications needing maximum conductivity and stability as the industries prioritizing purity and shift toward precision electronics and high-performance energy storage.

Purity Level Insights

How did the High Purity Segment Dominate the Aluminium Metal Powder Market?

The high-purity segment leads the market because advanced applications prioritize flawless material performance over cost efficiency. Industries like aerospace, medical, and electronics need high-purity aluminum for consistency and reliability, with Impurities that degrade electronic and battery performance. This segment offers optimal conductivity, corrosion resistance, and mechanical stability, making it essential for next-generation technology.

The commercial-grade segment is an emerging segment projected to grow at a CAGR between 2026 and 2035. Due to its cost-effectiveness for high-volume industrial applications, where extreme purity is not required. Its growth is driven by a surge in sustainable construction, especially lightweight, energy-efficient AAC blocks, and its widespread adoption for automotive parts and industrial coatings, enabling rapid scale-up while meeting demand for durable, accessible materials.

End-Use Sector Insights

How did the Automotive & Transportation Segment hold the Largest Share of the Aluminium Metal Powder Market?

The automotive and transportation segment holds the largest market share due to lightweighting and fuel efficiency goals. Aluminum powder is key for manufacturing high-strength, low-density components through powder metallurgy and additive manufacturing, especially in EVs where thermal conductivity supports battery cooling systems and motor housings, enabling the mass production of complex, weight-saving components across global supply chains.

The aerospace & defence segment is set to experience the fastest growth, because aluminum powders enable next-generation high-performance structural components and advanced propulsion systems, allowing weight optimization, fuel efficiency, and payload capacity, vital for high-performance applications like rocket propellants and defense systems. The ability to produce sophisticated,high-strength alloys driving the industry toward advanced, durable, high-value material solutions surpassing traditional metals in durability and mission success.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6135

Regional Insights

How did the Asia Pacific hold the Largest Share of the Aluminium Metal Powder Market?

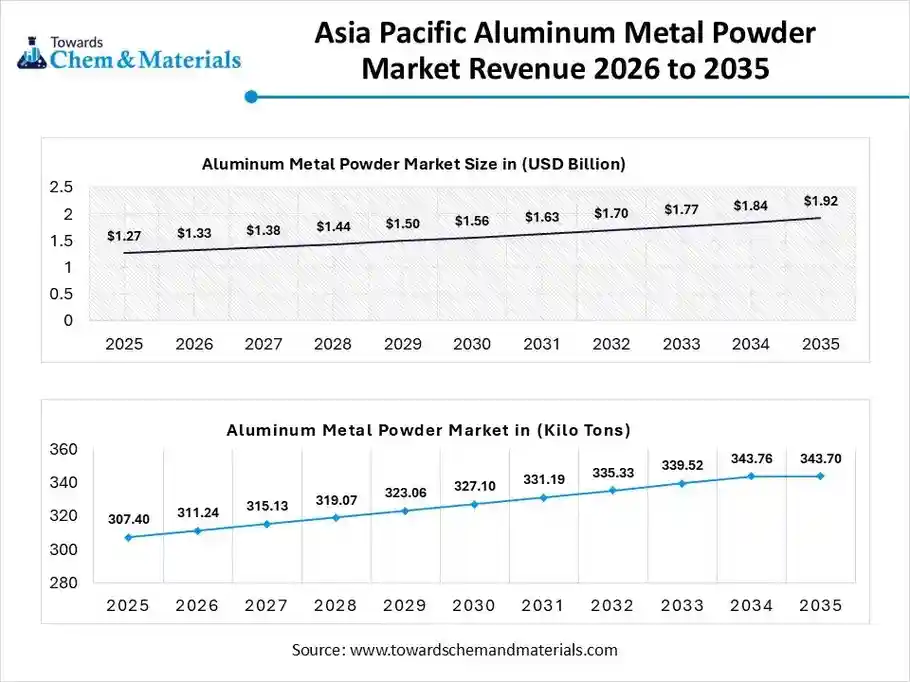

The aluminum metal powder market size was valued at USD 1.27 billion in 2025 and is expected to be worth around USD 1.92 billion by 2035, exhibiting at a compound annual growth rate (CAGR) of 4.21% over the forecast period from 2026 to 2035. the aluminum metal powder market volume was estimated at 307.4 kilo tons in 2025 and is projected to reach 343.7 kilo tons by 2035, growing at a CAGR of 1.25% from 2026 to 2035.

Asia Pacific dominated the market, driven by rapid urbanization and mass-scale industrial manufacturing by its capacity for electric vehicle and battery production, which is vital for lightweighting and thermal efficiency. The region serves as a crucial engine for high-volume commodity and material innovation due to its robust supply chain integrated with high tech sector like aerospace and renewable energy boosted its sustainable production combine with the increasing demand for AM, driving its dominance.

India Aluminium Metal Powder Market Trends

India's market is growing steadily, driven by rising demand from construction, paints and coatings, explosives, mining, and metallurgical applications. Increased use in automotive coatings, additive manufacturing, and lightweight components is further supporting market expansion. Emerging applications in renewable energy infrastructure and advanced manufacturing are creating new growth opportunities.

Why Aluminium Metal Powder Market Growing Rapidly in North America?

The North America region is fastest growing in market due to the rapid decarbonization of the automotive supply chain and a strategic shift towards high-value additive manufacturing. The surge in domestic electric vehicle production and integration of aluminum powder for 3D-printed components accelerated demand for specialized powders for thermal management and lightweight structural frames, supported by an emphasis on green aluminum to meet strict regional sustainability mandates.

U.S. Aluminium Metal Powder Market Trends

The U.S. market is expanding steadily, supported by strong demand from aerospace, automotive, defense, electronics, and industrial sectors that value lightweight, high-performance materials. Growth is being driven in part by increased adoption of additive manufacturing and powder metallurgy for complex, precision parts, especially in EVs, aircraft, and defense applications.

What is Going Around the Aluminium Metal Powder Industry

- In January 2026, Runaya Metsource and ECKART officially launched a joint venture facility in Odisha to produce gas-atomised aluminum powders in India. Focus on the production of spherical powders using the gas-atomization process that shifts towards domestic manufacturing in India for high-end sectors like aerospace, solar technology, and space exploration.

More Insights in Towards Chemical and Materials:

- Aluminum Flat Products Market Size to Hit USD 112.15 Bn by 2035

- Aluminum Extrusion Market Size to Surpass USD 224.18 Bn by 2035

- Aluminum Casting Market Size to Surpass USD 172.05 Bn by 2035

- Aluminum Composite Materials Market Size to Reach USD 8.18 Billion by 2034

- Aluminum Foil Market Size to Reach USD 48.46 Billion by 2034

- Aluminum Trihydrate (ATH) Market Volume to Hit 4653.45 Kilo Tons by 2034

- Aluminum Oxide Market Volume to Hit 215.45 Million Tons by 2034

- Metal Injection Molding Parts Market Size to Hit USD 18.58 Bn by 2035

- Additive Manufacturing With Metal Powders Market Size to Surpass USD 166.41 Bn by 2035

- Aluminum Metal Powder Market Size to Hit USD 4.15 Billion by 2035

- Lithium Metal Battery Materials Market Size to Hit USD 32.48 Bn by 2035

- Metal Stamping Market Size To Surpass USD 385.66 Billion By 2035

- Metal Recycling And Recovery Market Size to Surpass USD 957.06 Bn by 2035

- U.S. Metal Recycling Market Size to Reach USD 121.04 Billion by 2034

- Metal Recycling Market Size to Hit USD 1,071.11 Billion by 2034

- Asia Pacific Metal Casting Market Size to Hit USD 142.91 Billion by 2034

- Metal-Organic Frameworks Market Volume to Reach 3,43,966.3 Tons by 2034

- U.S. Metallocene LDPE Market Volume to Reach 669.44 Thousand Tons by 2034

- Metal Carboxylates Market Size to Hit USD 10.83 Billion by 2034

- Metal Casting Market Size to Expand USD 262.91 Bn by 2034

- Vinyl Acetate Monomer (VAM) Market Size to Hit USD 22.65 Billion by 2035

- Water Soluble Fertilizers Market Size to Surpass USD 46.36 Billion by 2035

- Semiconductor Chemicals Market Size to Hit USD 52.35 Billion by 2035

- Polyisobutylene Market Size to Reach USD 5.18 Billion by 2035

-

Biaxially Oriented Polypropylene (BOPP) Market Size to Hit USD 224.40 Billion by 2035

Top Market Players in Aluminium Metal Powder Market & Their Offerings:

Tier 1:

- MMP Industries Ltd. (India): Produces atomised, flake, and pyro powders for explosives, pesticides, and construction materials.

- The Metal Powder Company Limited (MEPCO): Manufactures spherical and atomised powders for aerospace, defense, and high-end automotive coatings.

- Valimet, Inc.: Specializes in high-purity spherical powders for rocket propellants, additive manufacturing, and thermal sprays.

- Höganäs AB: Provides specialized aluminium alloy powders designed for 3D printing and industrial surface coating applications.

- AMG Advanced Metallurgical Group: Supplies aluminium powders and master alloys used primarily for grain refining and deoxidizing in metal production.

- Toyo Aluminium K.K.: Produces advanced atomised powders and specialized pastes for the global automotive, ink, and electronics markets.

Tier 2:

- U.S. Metal Powders, Inc.

- Rusal (Russia)

- Kymera International

- ECKART GmbH (Germany)

- Zhangqiu Metallic Pigment Co., Ltd. (China)

- Xinfa Group Co., Ltd. (China)

- Arasan Aluminium Industries (P) Ltd. (India)

- CNPC Powder Group Co., Ltd. (China)

- Angang Group (China)

Aluminium Metal Powder Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2035. For this study, Towards Chemical and Materials has segmented the global Aluminium Metal Powder Market

By Product Type & Morphology

- Atomized Aluminum Powder

- Spherical Powder (High-flowability for 3D printing)

- Irregular/Granular Powder

- Aluminum Flakes

- Leafing Flakes (Surface-oriented for coatings)

- Non-Leafing Flakes (Deep-lustre for automotive paints)

- Specialty Aluminum Powders

- Ultra-fine/Nano Aluminum Powder

- Aluminum Alloy Powders (e.g., AlSi10Mg, Scalmalloy)

By Production Process (Technology)

- Atomization

- Gas Atomization (Inert gas for high purity)

- Air Atomization

- Water Atomization

- Mechanical Methods

- Ball Milling (Primary for flake production)

- Comminution

- Electrolysis & Chemical Reduction

By Purity Level

- Ultra-High Purity (>99.9%)

- High Purity (99.5% – 99.8%)

- Commercial Grade (92% – 99%)

By End-Use Sector

- Aerospace & Defense

- Automotive & Transportation

- Building & Construction

- Electrical & Electronics

- Renewable Energy (Solar/PV)

By Regional

North America:

- U.S.

- Canada

- Mexico

- Rest of North America

South America:

- Brazil

- Argentina

- Rest of South America

Europe:

- Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

Eastern Europe

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

Asia Pacific:

- China

- Taiwan

- India

- Japan

- Australia and New Zealand,

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

MEA:

- GCC Countries

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

- Rest of MEA

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6135

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics | TCM Blog

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.